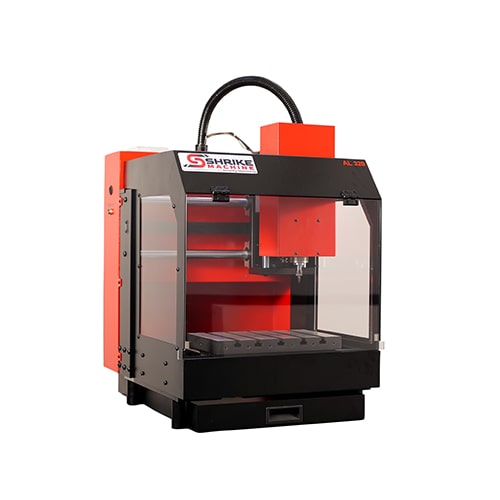

SHRIKE AL320

We are thrilled to announce our new Shrike AL320 Mobile cum desktop CNC Milling with this CNC Milling mill you can turn your ideas and design into reality. This is the most advanced and compact solution of machining with its plug-play type rotary axis working on cylindrical parts is easy like never before.

As Shrike CNC Milling comes up with compact and rigid it can easily handle some simple engraving like nameplate to high-speed metal cutting for precision parts.

Shrike CNC Milling is the perfect machining & engraving solution for micromachining, hardware products, brass parts, precision engraving, electronics, precision electrodes, automotive parts, dies and molds, plastic & toys, making watches, and gold jewelry.

| SPECIFICATION | SHRIKE AL320 |

|---|---|

| Working Area (X*Y*Z) | 315 * 250 * 140 mm |

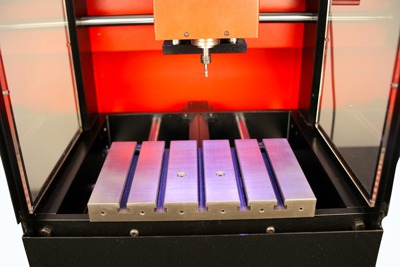

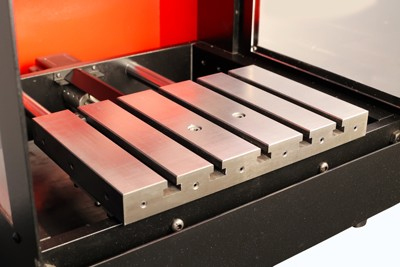

| T-Sloted Bed Size | 320*200mm |

| No of T-Slot | 5 |

| Spindle Power (KW) | 0.8 KW (Air Cooled) |

| Spindle Speed (RPM) (MAX) | 24000 |

| Tool Collete | ER 11 |

| Max Tool Size | 6 mm |

| Rapid Rate | 10000 mm / min |

| Accuracy | 0.02 mm |

| Repeatability | 0.01 mm |

| Motor / Drive | Stepper Motor & Drive |

| Drive System | Ball Screw |

| Guide System | Linear Motion Rod |

| Controller | Shrike contorller |

| NC File Format | ISO G-Code (Standard) |

| Power | 1.2 kw 1 Phase 220V |

| Machine Dimension (W*L*H) | 505*625*750mm |

| Approx Weight | 85 KGS |

Features

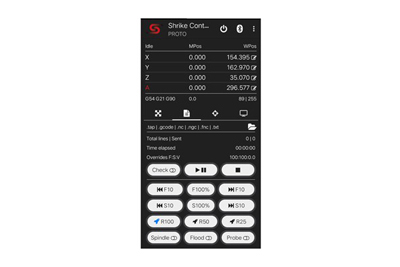

Mobile CNC Milling

We call this Mobile CNC Milling cause you can operate it wirelessly just by your android Mobile phone and it works smoothly on our Android Application and you can also connect your Mobile Phone via a USB OTG cable, Therefore there is no need to connect to a PC or Laptop. But if you want to use it as a desktop CNC Milling you can always connect your PC or Laptop by USB.

Smart Design & Rigid Structure

This CNC Milling is a masterpiece in terms of design cause its compact, efficient and low weight. Machine structure manufactured with high-quality aluminum grade 60-65 means this CNC Milling machine can stand up to tough jobs without any vibration.

Automatic Stock Location / Probing

Material probing routines help you set up works faster and avoid unnecessary mistakes. In our Android app, we give a dedicated window with 5 ready-to-use probe buttons that Shrike AL320 stock location is a super easy and time-saving process.

Note: Probing Must do with a 6 mm tool and probing only work with conductive materials.

End Less Possibilities

As Shrike CNC Milling comes up with compact and ready it can easily handle some simple engraving like nameplates to high-speed metal cutting for precision parts. It is a perfect solution for prototyping.

With very intelligent design it requires very less floor space so it will be a great solution for CAD-CAM institutions cause now with this Shrike CNC Milling their Student can practically learn how CNC Milling machine work and they can simply turn their ideas and design into a workpiece.

Shrike CNC Milling is the perfect machining and engraving solution for micromachining, hardware products, brass parts, precision engraving, electronics, precision electrodes, automotive parts, dies and molds, plastic items, and toys, making watches, gold jewelry.

Precision + Rigidity + Affordability

High-Speed Machining

With a 0.8 Kw 24000 RPM spindle, high precision LM Rod & bearings in guide system, Imported ball Screw-in drive system Shrike AL320 is capable of high-Speed machining with rapid rate of 12000 mm/min.

Fast Set Up

Using our probing feature, you can quickly fix a tool length, probe part geometry. With the use of our quick clamping vice on the t-slot bed you can quickly and easily load the workpiece into the machine.

Easy To Use

Shrike AL320 understands standard ISO G-code. Subsequently making it compatible with almost all CAM software. Our Android App (Shrike Controller) can easily operate with 6 type of files and they are .gcode, .tap, .nc, .ngc, .fnc, .txt .

T-Slotted Bed with Threaded Sides

Shrike AL320’s T-Slotted bedplate comes with 18 (6mm Threads) on 4 sides so you can easily set up any fixture outside the bed or you can set a stopper for production works.

Machine + Software + Traning

Real-Time Application Feedback

With Shrike Controller Application gets real-time machine coordinates and work coordinates. Users can also override spindle speed, feeds, and rapid rate even in between of machining process.

Enclosed Body With Best Visibility

The Shrike AL320 comes up with 2 mm thick sheet metal enclosures with 180-degree open-able transparent Acrylic Front Door and Transparent Acrylic window on both sides the visibility is unmatchable.

Material Processing Capabilities

Material that can be processed on Shrike AL320S include all materials of AL320 + any hard material Like Carbon Steel, Mild Steel and Stainless Steel.

Plug & Play Type 4th Axis

Working on cylindrical parts is super easy with shrike AL320 setup rotary axis in just a matter of minutes with our plug and play design just plug the rotary axis and setup it with just 2 bolts on T-slotted bed.